The new PM would have a capacity of 600,000 tpy, final decision is expected in H1 2023.

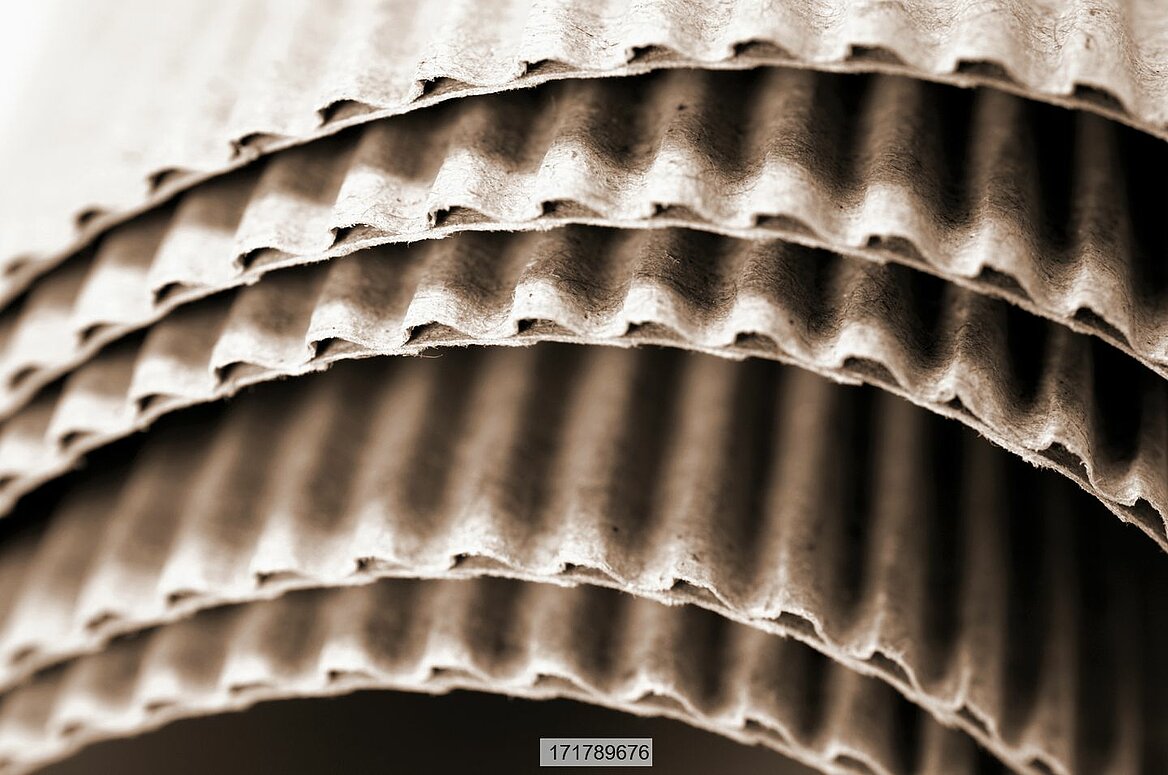

German containerboard producer Varel is considering building a new mill to make ultra-lightweight recycled corrugated case material at an additional site in Wilhelmshaven, Germany. The company announced that it was engaged in intensive preparatory planning for the project; Varel was looking into adding another production line for ultra-lightweight recycled paper for the German and international corrugated board industry. The favoured location in Wilhelmshaven is on the site of a closed Uniper coal-fired power plant. Varel is embroiled in in-depth discussions with Uniper about the site.

The planned machine will have a capacity of 600,000 tpy and be designed to make ultra-lightweight grammages starting at 60 g/m2, according to Varel. The firm expects to make a final decision on the project in the first half of next year, with production starting in 2026 at the earliest. At present the company has total output capacity of about 930,000 tpy of recycled solid board and recycled fluting and brown and white recycled liner as well as a number of composite materials.

Varel feels that the market for sustainable packaging materials has potential and feels that ultra-lightweight packaging paper will be essential to next-generation fibre-based packaging. The site in Wilhelmshaven could work towards climate-neutral manufacturing from the outset, the firm said, adding that potential wind and solar power sources and green hydrogen offered a wide variety of opportunities to do so. Linking green energy, waste heat and water will be part of the overriding energy strategy. The project is to receive support from the Energy Hub Port of Wilhelmshaven and the Fraunhofer Institute for Surface Engineering and Thin Films Braunschweig in this area.